It’s your job to make sure the world keeps moving … and to do that, you need ice control equipment you can rely on. The all-new MARAUDER stainless steel hopper lineup is engineered to get the job done right. Choose the best material delivery system for your operation based on the de-icer you commonly use … either the all-new HELIXX™ shaftless auger for precise rock salt application or the pintle chain conveyor that’s perfect for thick, heavy de-icing materials. Whatever choice you make, you’ll get the delivery performance you demand.

HELIXX™ Auger Technology

Patented corkscrew material delivery system is optimized to operate in the target range for rock salt spreading best practices. The auger has multiple pitches to help promote smooth, even material flow from the hopper and prevents bridging. The shaftless technology reduces drag on the motor and reduces the overall load on the electrical system.

PINTLE CHAIN CONVEYOR

The large conveyor delivers reliable, smooth, and consistent material flow for heavy, dense materials while reducing bridging.

* Chain Models Only (S150C, S220C, S300C, S400C, S500C)

HOPPER CONSTRUCTION

The hopper is made from corrosion-resistant stainless steel and constructed entirely of rivets and bolts, with no welding. This provides a cleaner stainless look and is easier to repair for long-life and protection against stress.

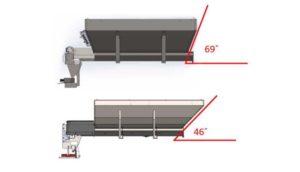

Steeper End Caps

The end caps are at more of an angle to provide better material flow so the hopper load can be evenly spread with each fill.

CHUTE DESIGN

Baffles within the chute deliver a consistent spread pattern that reduces material waste. By directing material to precise points on the spinner, it helps to cast it away from the truck rather than onto the back of your bumper. A direct drive motor offers better torque and reduces servicing.

CHUTE ASSEMBLY

For precise material application, the chute assembly can be configured for either pickup truck or flatbed and dump body applications, ensuring you’re always spreading at the optimum height. An extended chute is standard on 3.0, 4.0, and 5.0 cu yd models. Sold separately for 1.5 and 2.2 cu yd models.

The ergonomic, hinged design opens from the driver’s side and swings to the passenger side, providing easy access for maintenance or material unloading. For convenient access to the hitch, the chute assembly can be removed.

Product SPECS

* C = Pintle Chain Conveyor / A = HELIXX Shaftless Auger

* Material weight equates to approximately 2,160 lb/cu yd or 80 lb/cu ft for 1 bag of rock salt.

Reviews

There are no reviews yet